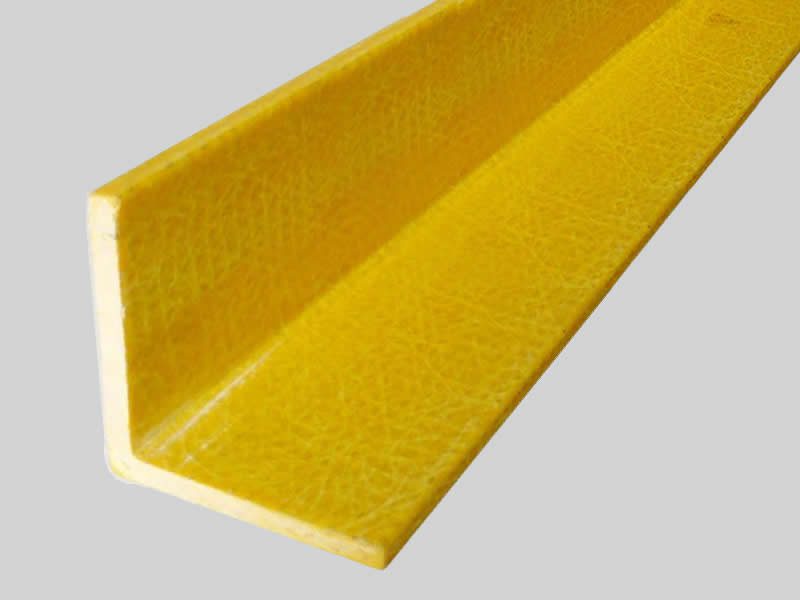

FRP Angle Profiles, also known as Fiberglass L Profiles, Pultruded FRP Angles, or GRP Angle Beams, are high-strength, lightweight structural components manufactured using advanced pultrusion technology. Made from continuous glass fiber yarns embedded in a thermosetting resin matrix, these FRP profiles offer outstanding mechanical and chemical performance. Designed for structural stability and long-term durability, FRP angles are the ideal substitute for traditional materials such as steel, aluminum, or timber.

Features of FRP Angle Profiles

- Lightweight and High Strength: These FRP profiles offer a tensile strength of up to 600 MPa while being significantly lighter than steel or aluminum. This reduces structural load and makes handling and installation easier.

- Corrosion and Weather Resistant: Designed for aggressive environments, FRP angles resist moisture, salt, acids, and other chemicals, making them perfect for outdoor and industrial applications.

- Thermal and Electrical Insulation: FRP angles are non-conductive, making them suitable for use around live electrical components and in high-voltage environments.

- Dimensional Stability: With a low coefficient of thermal expansion, these profiles maintain their shape and size under fluctuating temperatures.

- Easy to Machine and Customize: FRP angle profiles can be easily cut, drilled, or shaped using standard tools—similar to working with wood but with superior durability.

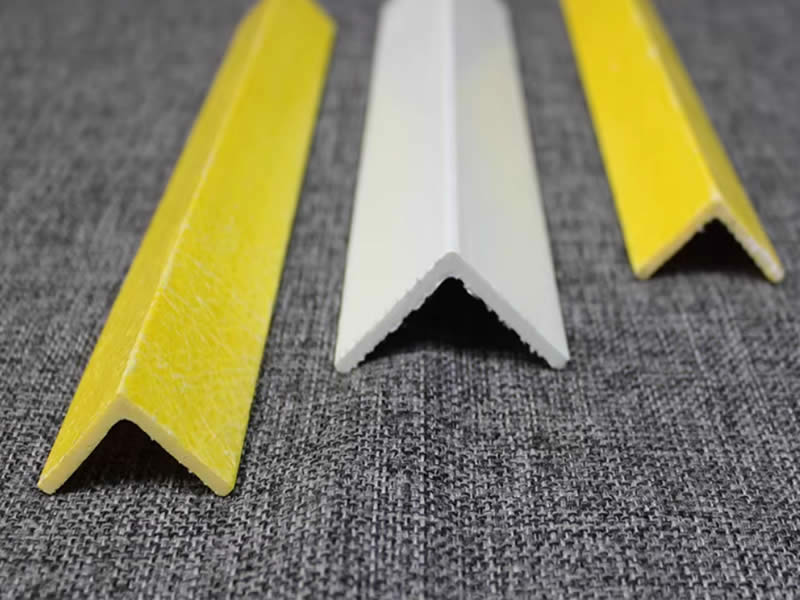

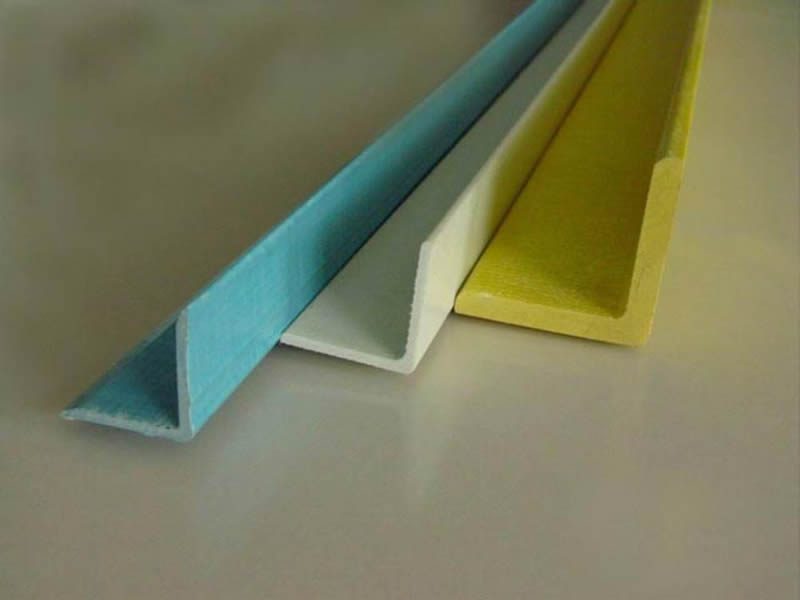

- Aesthetic and Maintenance-Free: Available in a wide range of colors and finishes, they require no coating or painting and offer excellent UV resistance.

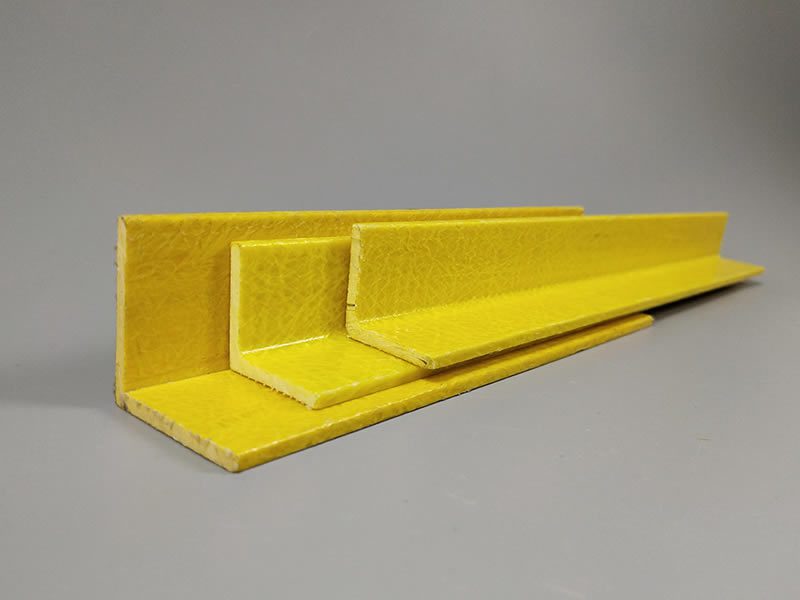

Specifications of FRP Angle Profiles

FPR Angle/ L Beam Profiles Available:

| FRP Angle/ L Beam Profiles | |||

| A(inch) | B(inch) | T1(inch) | T2(inch) |

| 0.98 | 0.98 | 0.10 | 0.10 |

| 1.38 | 1.38 | 0.16 | 0.16 |

| 1.57 | 1.57 | 0.16 | 0.16 |

| 1.59 | 0.98 | 0.16 | 0.16 |

| 1.69 | 1.69 | 0.20 | 0.20 |

| 1.97 | 1.97 | 0.26 | 0.26 |

| 2 | 1.5 | 0.13 | 0.13 |

| 2.13 | 2.13 | 0.16 | 0.16 |

| 2.99 | 2.99 | 0.24 | 0.24 |

| 2.99 | 2.99 | 0.37 | 0.37 |

| 3.94 | 3.94 | 0.37 | 0.37 |

| 4.92 | 4.92 | 0.39 | 0.39 |

| 5.51 | 2.52 | 0.31 | 0.31 |

| 5.51 | 2.52 | 0.39 | 0.39 |

FRP Angle/ L Beam Profiles Available:

| FRP Angle/ L Beam Profiles | |||

| A(mm) | B(mm) | T1(mm) | T2(mm) |

| 25 | 25 | 2.5 | 2.5 |

| 35 | 35 | 4 | 4 |

| 40 | 40 | 4 | 4 |

| 40.5 | 25 | 4 | 4 |

| 43 | 43 | 5 | 5 |

| 50 | 50 | 6.5 | 6.5 |

| 50.8 | 38.1 | 3.2 | 3.2 |

| 54 | 54 | 4 | 4 |

| 76 | 76 | 6 | 6 |

| 76 | 76 | 9.5 | 9.5 |

| 100 | 100 | 9.5 | 9.5 |

| 125 | 125 | 10 | 10 |

| 140 | 64 | 8 | 8 |

| 140 | 64 | 10 | 10 |

Applications of FRP Angle Profiles

Due to their unmatched resistance to harsh conditions, FRP angle profiles are used across various industries:

- Construction and Civil Engineering: Bridges, stair supports, roof frames, and edge protection.

- Chemical Plants and Refineries: Structural frameworks in corrosive environments.

- Cooling Towers and Desalination Plants: Support elements in moisture-prone areas.

- Marine and Offshore: Durable components exposed to saltwater and humidity.

- Rail and Electrical Infrastructure: Insulated supports and framing for cables and equipment.

- Wastewater and Sewage Treatment: Long-lasting framing for non-slip walkways and grating support.

- Solar Panel Structures: Lightweight yet strong mounting frames.

Advantages of Pultruded FRP Angles

- 30–70% lighter than steel or aluminum

- Consistent quality due to continuous manufacturing

- Low maintenance and long service life

- CE-marked for traceable, verified quality

- Electromagnetic transparency and non-magnetic behavior

- Safer and faster installation—can be pre-assembled off-site

Customized FRP Angle Solutions

We provide tailored FRP profiles including cut-to-size services, hole drilling, and integration with other structural components. Whether you’re working on infrastructure, utilities, or industrial projects, our fiberglass angles can be adapted to your exact requirements.