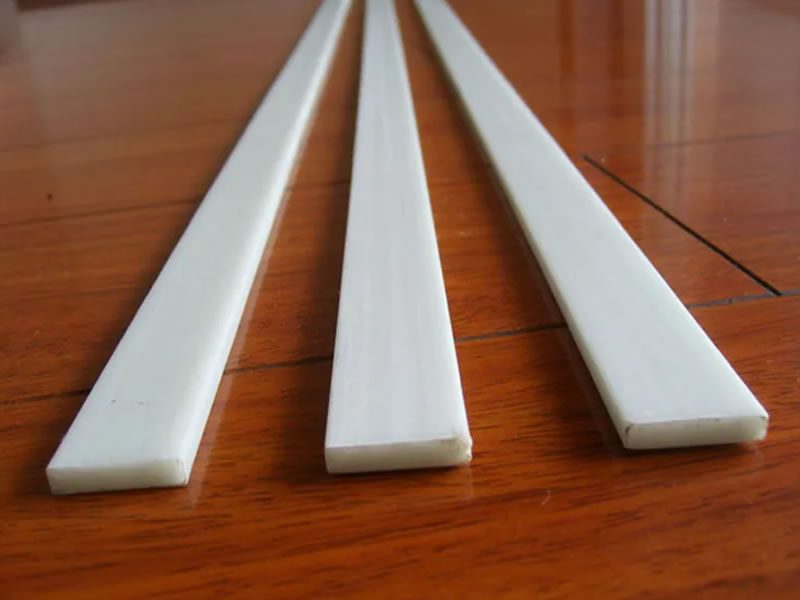

Fiberglass FRP strip profiles are flat, elongated structural elements composed of fiber-reinforced polymer (FRP) composites. Manufactured via a precision pultrusion process, they are produced by pulling continuous fiber reinforcements through resin impregnation and a thermally controlled die. This method ensures consistent cross-sectional geometry and improved material uniformity.

Core Advantages

- Optimized Weight-to-Strength Ratio: Significantly lighter than metals like steel or aluminum, reducing logistical costs and enhancing energy efficiency in transportation applications.

- Exceptional Mechanical Properties: High tensile strength (400–800 MPa) and flexural resilience enable reliable performance in structural and dynamic load-bearing environments.

- Environmental Durability: Inherent resistance to corrosion, UV degradation, and moisture ensures longevity in harsh industrial or outdoor settings.

- Thermal Stability: Minimal thermal expansion maintains dimensional accuracy across temperature fluctuations (-40°C to +120°C).

- Electrical Safety: Non-conductive properties make them ideal for electrical insulation components and high-voltage environments.

Customization & Adaptability

- Tailored dimensions, surface textures, and color finishes to align with project-specific needs.

- Compatible with epoxy, polyester, vinyl ester, and phenolic resins, offering flexibility in chemical resistance and mechanical performance.

- Easily machined, drilled, or bonded using standard tools for seamless integration into diverse systems.

Industry Applications

- Infrastructure: Structural supports, roofing systems, and corrosion-resistant cladding in construction.

- Transportation: Vehicle chassis components, lightweight panels, and cargo accessories.

- Energy & Utilities: Cable management systems, transformer insulation, and utility pole reinforcements.

- Agriculture & Recreation: Greenhouse frameworks, sports equipment (e.g., fishing rods, ski cores), and durable outdoor installations.

Technical Specifications

- Density: 1.6–2.0 g/cm³ (varies with resin type).

- Thermal Conductivity: 0.04–0.4 W/m·K, ensuring energy efficiency in thermal management.

- Surface Finish: Smooth, UV-stable coatings available in customizable colors and patterns.

| Product Number | B | T | A | Wt. |

| mm | mm | 10³ mm² | kg/m | |

| FS19x6.4 | 19.0 | 6.4 | 0.122 | 0.25 |

| FS25.4×8 | 24.4 | 8.0 | 0.195 | 0.40 |

| FS30x3 | 30.0 | 3.0 | 0.090 | 0.70 |

| FS30x6.4 | 30.0 | 6.4 | 0.192 | 0.37 |

| FS35x8 | 35.0 | 8.0 | 0.280 | 0.54 |

| FS38x5 | 38.0 | 5.0 | 0.190 | 0.37 |

| FS40x8 | 40.0 | 8.0 | 0.320 | 0.62 |

| FS50x2 | 50.0 | 2.0 | 0.100 | 0.25 |

| FS50x4 | 50.0 | 4.0 | 0.200 | 0.38 |

| FS50x6 | 50.0 | 6.0 | 0.300 | 0.59 |

| FS50x8 | 50.0 | 8.0 | 0.400 | 0.76 |

| FS50x15 | 50.0 | 15.0 | 0.750 | 1.43 |

| FS50x25 | 50.0 | 25.0 | 1.250 | 2.50 |

| FS102x5 | 102.0 | 5.0 | 0.510 | 0.97 |

| FS120x10 | 120.0 | 10.0 | 1.200 | 2.40 |

| FS152x10 | 152.0 | 10.0 | 1.520 | 2.92 |

| FS250x12 | 250.0 | 12.0 | 3.000 | 5.70 |