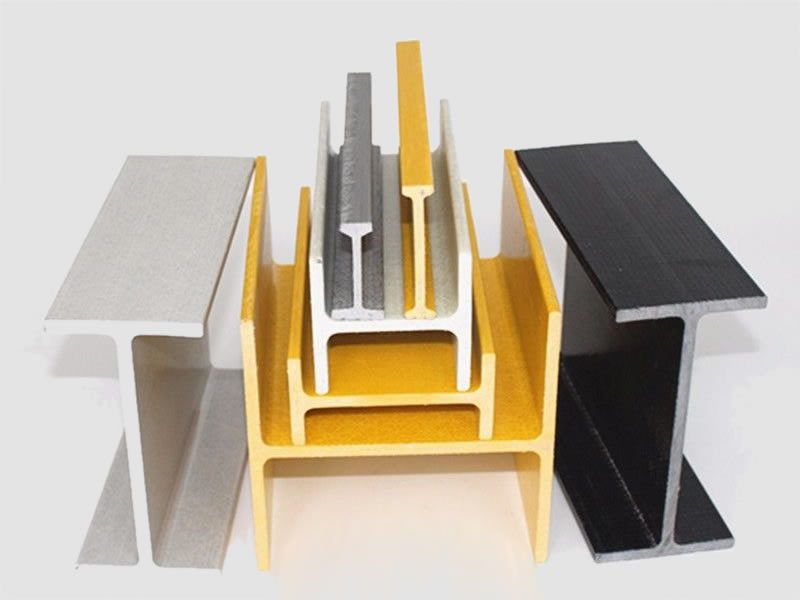

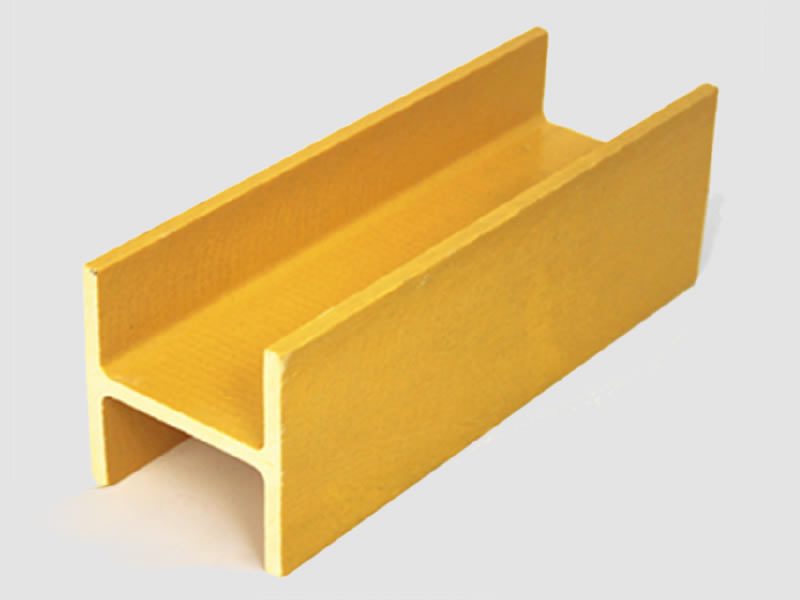

FRP I Beams combine the mechanical properties of fiberglass with the benefits of thermosetting resin, providing a lightweight, high-strength material ideal for use in structural, mechanical, and architectural applications. These FRP profiles are used extensively in construction, bridges, roads, and as reinforcement materials in various projects due to their superior corrosion resistance, durability, and reliability.

Specifications

Our FRP I Beam Profiles come in a variety of sizes and configurations to suit different structural needs.

Fiberglass I Beam/ H Beam Available:

| Fiberglass I Beam/ H Beam | |||

| A(inch) | B(inch) | T1(inch) | T2(inch) |

| 0.49 | 0.98 | 0.16 | 0.16 |

| 0.59 | 0.98 | 0.13 | 0.13 |

| 0.59 | 1.50 | 0.16 | 0.16 |

| 0.59 | 2.28 | 0.16 | 0.16 |

| 0.59 | 2.76 | 0.24 | 0.24 |

| 0.98 | 0.98 | 0.12 | 0.12 |

| 0.98 | 1.18 | 0.13 | 0.13 |

| 1.06 | 1.26 | 0.20 | 0.20 |

| 1.18 | 1.50 | 0.16 | 0.16 |

| 1.18 | 3.15 | 0.13 | 0.13 |

| 1.22 | 2.56 | 0.20 | 0.18 |

| 1.57 | 1.57 | 0.56 | 0.56 |

| 1.93 | 1.93 | 0.56 | 0.56 |

| 1.97 | 3.94 | 0.20 | 0.20 |

| 2.05 | 4.02 | 6.4 | 6.4 |

| 0.24 | 4.72 | 0.24 | 0.24 |

| 2.48 | 2.48 | 0.14 | 0.14 |

| 2.99 | 5.98 | 0.25 | 0.25 |

| 3.94 | 4.13 | 0.24 | 0.24 |

| 3.94 | 7.87 | 0.39 | 0.39 |

| 4.92 | 5.91 | 0.39 | 0.39 |

| 4.92 | 5.91 | 0.47 | 0.47 |

| 5.91 | 11.81 | 0.59 | 0.59 |

| 7.99 | 7.99 | 0.47 | 0.47 |

Fiberglass I Beam/ H Beam Available:

| Fiberglass I Beam/ H Beam | |||

| A(mm) | B(mm) | T1(mm) | T2(mm) |

| 12.5 | 25 | 4 | 4 |

| 15 | 25 | 3.2 | 3.2 |

| 15 | 38 | 4 | 4 |

| 15 | 58 | 4 | 4 |

| 15 | 70 | 6 | 6 |

| 25 | 25 | 3 | 3 |

| 25 | 30 | 3.2 | 3.2 |

| 27 | 32 | 5 | 5 |

| 30 | 38 | 4 | 4 |

| 30 | 80 | 3.2 | 3.2 |

| 31 | 65 | 5 | 4.5 |

| 40 | 40 | 3 | 3 |

| 49 | 49 | 3 | 3 |

| 50 | 100 | 5 | 5 |

| 52 | 102 | 6.4 | 6.4 |

| 60 | 120 | 6 | 6 |

| 63 | 63 | 3.5 | 3.5 |

| 76 | 152 | 6.4 | 6.4 |

| 100 | 105 | 6 | 6 |

| 100 | 200 | 10 | 10 |

| 125 | 150 | 10 | 10 |

| 125 | 150 | 12 | 12 |

| 150 | 300 | 12 | 12 |

| 200 | 200 | 15 | 15 |

| 203 | 203 | 12 | 12 |

Note: Additional custom sizes and lengths are available on request.

Features of FRP I Beam Profiles

- High Strength-to-Weight Ratio: Despite being lightweight, FRP I beams offer exceptional strength, making them suitable for heavy load-bearing applications.

- Corrosion Resistance: Ideal for use in environments exposed to moisture, chemicals, and saltwater, these beams maintain their integrity over time.

- Flame Retardant & Non-Conductive: These beams are non-magnetic and offer excellent electrical and thermal insulation properties, ensuring safety in industrial environments.

- Low Thermal Expansion: FRP profiles exhibit minimal expansion or contraction under temperature fluctuations, ensuring structural stability.

- Aging Resistance: With high UV and environmental resistance, these beams retain their performance and appearance even in harsh outdoor conditions.

- Customizable Design: Available in various sizes, colors, and custom configurations to meet specific engineering needs.

Applications of FRP I Beam Profiles

- Structural Support: Used in building frameworks, bridges, and industrial platforms for added strength and durability.

- Mechanical Reinforcement: Ideal for mechanical frames, supports, and bracketing systems in manufacturing plants.

- Chemical & Marine Applications: FRP I beams are perfect for environments exposed to corrosive chemicals, seawater, and other harsh conditions.

- Electrical Engineering: Employed in cable support systems and as electrical insulators, benefiting from their non-conductive properties.

Why Choose FRP I Beam Profiles?

- Durability: Long-lasting and low-maintenance, providing excellent performance even in harsh conditions.

- High Strength and Low Weight: Ideal for structural applications requiring both strength and lightweight solutions.

- Customization: Tailored to meet specific project requirements with flexible size, shape, and color options.

- Environmental Resistance: Superior performance in corrosive, UV-exposed, and high-temperature environments.